Description

PINS

- Carbon steel.

- It is treated to be heat treated for greater durability and strength.

- Core – Hardened to provide greater impact resistance.

- Surface – Induction or Case made harder for longer wear resistance.

- Made with precision to ensure the highest interference with sidebars.

- This prevents pin rotation and sidebar wear.

BUSHINGS

- Carbon or alloy of premium quality steel.

- A process of heat treatment to increase strength.

- Core – Hardened to ensure toughness and resistance to impact.

- The surface is hardened by the case to provide maximum wear resistance and increased durability.

- Machined precisely to ensure smooth bearing surfaces as well as a good interference fit to sidebars.

- Good residual stresses are able to can withstand fatigue and provide longer life.

SIDEBARS

- Carbon or alloy of premium quality steel.

- Through hardened to provide superior strength, toughness, and fatigue resistance.

- Proprietary manufacturing processes guarantee consistency in hole quality and precision pitch control.

- Residual stresses that are strong and durable prevent fatigue and permit longer life.

APPLICATIONS TYPICAL

Bulk Material Handling

- Bucket Elevators

- Feeders

- Drag Conveyors

Common Industries

MINERALS INDUSTRIALS

Mining

CEMENT

GRAIN

FERTILIZER

PROCESSING OF SUGAR

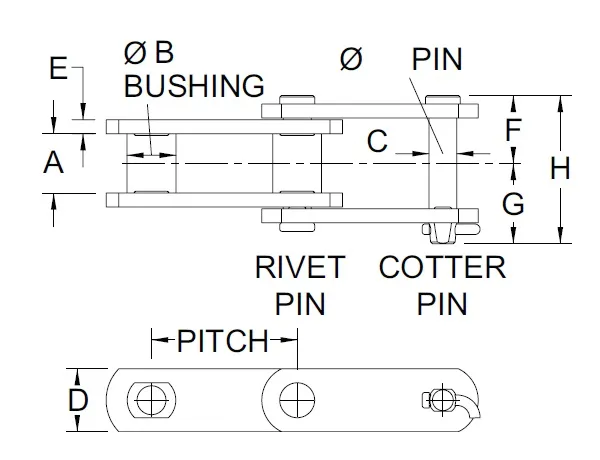

| 188 | 2.609 in | 1.06 in | 0.88 in | 0.50 in | 1.13 in | 0.25 in | 1.22 in | 1.44 in | 2.66 in | 25000 lb | 2750 lb |

| 131 | 3.075 in | 1.31 in | 1.25 in | 0.63 in | 1.50 in | 0.38 in | 1.59 in | 1.88 in | 3.47 in | 40000 lb | 4500 lb |

| 102B | 4.000 in | 2.13 in | 1.00 in | 0.63 in | 1.50 in | 0.38 in | 2.00 in | 2.28 in | 4.28 in | 40000 lb | 6300 lb |

| 102-1/2 | 4.040 in | 2.25 in | 1.38 in | 0.75 in | 1.75 in | 0.38 in | 2.06 in | 2.47 in | 4.53 in | 50000 lb | 8850 lb |

| 111 | 4.760 in | 2.63 in | 1.44 in | 0.75 in | 2.00 in | 0.38 in | 2.28 in | 2.66 in | 4.94 in | 50000 lb | 8850 lb |

| 110 | 6.000 in | 2.13 in | 1.25 in | 0.63 in | 1.50 in | 0.38 in | 2.00 in | 2.28 in | 4.28 in | 40000 lb | 6300 lb |

| 833 | 6.000 in | 2.63 in | 1.44 in | 0.75 in | 2.00 in | 0.38 in | 2.34 in | 2.66 in | 5.00 in | 74500 lb | 8850 lb |

| 150X | 6.050 in | 3.31 in | 1.75 in | 1.00 in | 2.50 in | 0.50 in | 2.94 in | 3.37 in | 6.31 in | 100000 lb | 15100 lb |

| 856 | 6.000 in | 3.00 in | 1.75 in | 1.00 in | 2.50 in | 0.50 in | 2.78 in | 3.22 in | 6.00 in | 145000 lb | 14000 lb |

| 956 | 6.000 in | 3.00 in | 1.75 in | 1.00 in | 3.00 in | 0.50 in | 2.78 in | 3.22 in | 6.00 in | 160000 lb | 14000 lb |

| 857 | 6.000 in | 3.00 in | 1.75 in | 1.00 in | 3.25 in | 0.50 in | 2.78 in | 3.22 in | 6.00 in | 174000 lb | 14000 lb |

| 958 | 6.000 in | 3.00 in | 1.99 in | 1.19 in | 3.38 in | 0.56 in | 2.84 in | 3.28 in | 6.13 in | 206000 lb | 17000 lb |

| 859 | 6.000 in | 3.75 in | 2.38 in | 1.25 in | 4.00 in | 0.63 in | 3.41 in | 3.84 in | 7.25 in | 264000 lb | 21800 lb |

| 864 | 7.000 in | 3.75 in | 2.38 in | 1.25 in | 4.00 in | 0.63 in | 3.41 in | 3.84 in | 7.25 in | 275000 lb | 22000 lb |

| 984 | 7.000 in | 3.75 in | 2.50 in | 1.38 in | 4.00 in | 0.63 in | 3.41 in | 3.84 in | 7.25 in | 285000 lb | 24000 lb |