Chain

Produces high-quality products that are suitable for a range of applications and industries, such as conveyor chains, roller chain chains, sprockets and hose-carrying systems, backstops, clutches and clutches and flexible cables that are continuous.

How Do Roller Chains Work?

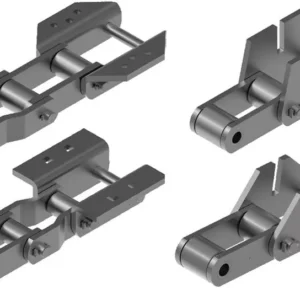

Roller chains are powered by moving sprockets that are connected to a motor that turns the chain. In the majority of chains, two kinds of links are employed in combination to work.

◆ Inner Link (also known as Roller Link): The two plates inside are joined by bushings or two bushings which are placed beneath each of the rollers.

◆ Outer Link (also known as Pin Link): Two outer plates that are joined through a pin that passes through the bushing of the inner link.

The conditions where your chain is utilized and the function it serves will determine which kind of chain to choose and the frequency you will have to replace it. Be assured that roller chains are among the most efficient and effective choices for transportation and power transmission applications.

Chain for Sale

As a chain manufacturer, we will do our best to serve you. If you need customized products, or the products you need are not found on our website, or need a product catalog, don’t worry, more of our products are still being uploaded. You can email us directly, and we will reply to you within 24 hours!

Benefits and Applications

Industrial roller chains and sprockets offer several benefits in industrial applications, including:

Power transmission: Roller chains and sprockets efficiently transfer power from one component to another, enabling the operation of various machinery and equipment.

Versatility: They can accommodate a wide range of operating conditions, including high loads, high speeds, and challenging environments.

Adjustable speed ratios: By using different-sized sprockets, speed ratios can be adjusted to meet specific application requirements, allowing for speed reduction or speed increase as needed.

Flexibility: Roller chains and sprockets can be easily configured in different arrangements to accommodate complex machinery layouts and various power transmission paths.

Industrial roller chains and sprockets find applications in diverse industries such as manufacturing, automotive, mining, agriculture, construction, and material handling. They are commonly used in conveyor systems, power transmission systems, machinery drives, lifting equipment, and many other industrial applications where reliable and efficient power transfer is essential.

Industrial Roller Chain & Sprockets

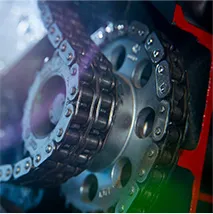

Industrial roller chains and sprockets are widely used in various industries for power transmission and motion control applications. They form a critical component of many mechanical systems, providing reliable and efficient power transfer. Here’s an overview of industrial roller chains and sprockets:

Industrial Roller Chains

Industrial roller chains are durable and versatile chains designed to transmit power between two or more sprockets. They consist of a series of interconnected links, typically with roller bearings placed between the inner plates and bushings or pins connecting the inner and outer plates. The rollers allow smooth rotation, reducing friction and wear.

These chains are available in different sizes and configurations to accommodate a wide range of power transmission requirements. They are commonly categorized based on their pitch (the distance between the centers of adjacent chain pins) and their strength or load capacity.

Industrial Sprockets

Sprockets are toothed wheels or gears with specially shaped teeth designed to engage with the rollers or links of a roller chain. They are typically made of high-quality materials such as steel or alloy, ensuring durability and resistance to wear. Sprockets come in various designs, including simplex, duplex, and triplex, depending on the number of chain rows they engage with.

The teeth of the sprockets are carefully engineered to match the pitch and roller diameter of the corresponding roller chain. They provide positive engagement, transferring torque and rotational motion from the driving sprocket to the driven sprocket or other components within the system.

How Roller Chains Increase the Power of Work

Roller chains are mechanical devices commonly used for power transmission in various applications. They consist of a series of interconnected links that form a flexible, yet strong, continuous chain. Roller chains are primarily designed to transmit rotary motion between two or more sprockets, thereby transferring power from one part of a system to another.

Efficient Power Transmission

Roller chains are designed to transmit power efficiently with minimal energy losses. They are made of high-quality materials, such as alloy steel, and are precisely manufactured to minimize friction and maximize power transfer. This efficiency ensures that a significant portion of the input power is effectively utilized in performing useful work.

Load Capacity

Roller chains are capable of handling high loads and transmitting substantial amounts of power. The individual links of the chain are designed to withstand tension, compression, and bending forces, allowing them to carry heavy loads without breaking or deforming. This load-carrying capacity enables roller chains to transmit greater power in applications where high torque or force is required.

Speed Ratios

By varying the size of the sprockets connected by the roller chain, different speed ratios can be achieved. Speed ratio refers to the ratio of the rotational speed of the driving sprocket to that of the driven sprocket. By increasing or decreasing the sprocket sizes, the output speed can be adjusted accordingly. This feature allows roller chains to convert high-speed, low-torque input power into lower-speed, higher-torque output power, or vice versa, depending on the specific requirements of the application.

Experience and Realiability You Can Count On

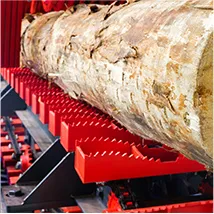

EPT is a reputable name in the field of industrial manufacturing. Since its inception, EPT has led technological advancement, innovation, and design, making sure you have the correct chain for your needs and has reduced lead times. Our commitment to quality and customer service allows us to keep exceeding the expectations of our customers and find the perfect chain for any application and scenario. We provide reliable, sturdy solutions that include engineered chains, block roller chains, casting chain roller chains, and many others. Industries that are heavy, such as cement, sugar mills mining, and timber depend on the EPT chain for the transportation of their products, and with good reason. Every time it has been proven that the EPT chain of industry stands out from the rest with top-quality of products, independent testing of the product, and expert engineering.

APPLICATION

Wastewater Products

Sugar Mill Chain

Agricultural Products

Cotton Module Truck Chain

Peanut Elevator Chain

Grain Handling Products

Sawmill & Lumber

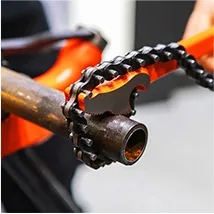

Pipe Wrench Chain

Wash Box Chain

Speciality Chain

Longer Chain Life Means Reduced Downtime

If your equipment is damaged it costs you a lot and not just in repair, downtime, and replacement expenses, but also in the time of maintenance staff and in security. The best industrial chains perform in areas where other chains do not. In extreme conditions, harsh environments, and heavy loads the EPT industry chain is superior to the competition time and time. We provide heat-treated chain, which includes case-hardened and induction-hardened chain – the best quality industrial chain that has unbeatable durability. EPT Industrial Chain will not hinder your operations because of unplanned downtime and it will not increase your expenses throughout the duration of the life cycle that your machine. Employing the latest techniques for manufacturing Our chains are designed to last longer in the most extreme conditions. Don’t let a chain’s failure hinder your productivity or efficiency. Depend on EPT chains that are durable.

Choose A High-quality Loose Chain Supplier

If you are looking for a bulk chain supplier, then EPT has what you need. Whether you work in aerospace, mining, agriculture, or one of many other industries, stainless steel chains will come in handy.

Hours

Mon – Fri: 9:00 AM – 10:00 PM